Putkiuunit - Nabertherm

Putkiuunit aina 1800 °C saakka - Nabertherm

Käyttämällä laajaa valikoimaa lisävarusteita, nämä ammattimaiset putkiuunit voidaan optimoida täydellisesti prosessiisi.

Pienikokoiset putkiuunit Tmax 1100 °C

RD 30/200/11 putkiuuni tekee vaikutuksen erittäin hyvällä hinta-laatusuhteellaan, erityisen kompaktilla ulkomitoillaan ja sen pienellä painolla. Tämä monitoimiuuni on varustettu työputkella, joka toimii myös lämmityslankojen tukena. Työputki on siis osa uunin lämmitystä, mikä on etu, sillä putkiuuni saavuttaa erittäin nopeat lämmitysnopeudet. Uuni on suunniteltu vaakakäyttöön jopa 1100 °C asti.

Ominaisuudet

- Tmax 1100 °C

- Kaksoiskuorirakenne, joka on valmistettu tekstuuripintaisista ruostumattoman teräksen levyistä ja lisäksi varustettu tuulettimella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan

- Putken sisähalkaisija: 30 mm, lämmitetty pituus: 200 mm

- Keraaminen työputki C 530, johon sisältyy kaksi kuitutulppaa käytettäväksi ilman kanssa

- K-tyypin lämpöpari (1100 °C)

- Kiinteät tilareleet takaavat hiljaisen toiminnan

- Lämmityslangat on kierretty suoraan työputken ympärille, mikä johtaa erittäin nopeisiin lämpenemisnopeuksiin

- Määritelty käyttö käyttöohjeiden rajoissa Ohjain R7

Pienikokoiset putkiuunit Tmax 1300 °C

Nämä kompaktit putkiuunit integroiduilla ohjausjärjestelmillä soveltuvat monipuolisesti moniin prosesseihin. Vakiovarusteena olevan C 530 keraamisen työputken ja kahden kuitutulpan ansiosta näillä putkiuuneilla on erittäin hyvä hinta-laatusuhde.

Ominaisuudet

- Tmax 1200 °C tai 1300 °C

- Yksialueinen rakenne

- Kaksoiskuorirakenne tekstuuripintaisista ruostumattoman teräksen levyistä lisätuuletuksella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan

- Ulkoputken halkaisija 50 mm – 170 mm, lämmitetty pituus 250 mm – 1000 mm

- Keraaminen työputki C 530 sisältäen kaksi kuitutulppaa käytettäväksi ilman kanssa

- Lämpöpari tyyppi N (1200 °C) tai tyyppi S (1300 °C)

- Kiinteät tilareleet takaavat hiljaisen toiminnan

- Tukiputkille asennetut lämmityselementit mahdollistavat vapaan säteilyn

- Määritelty käyttö käyttöohjeiden rajoissa

- NTLog Basic Nabertherm-ohjauslaitteelle: prosessitietojen tallennus USB-muistitikulle

- Ohjain B510 (5 ohjelmaa, joista jokaisessa 4 segmenttiä)

Splitti tyyliset putkiuunit horisontaaliseen tai vertikaaliseen toimintaan Tmax 1300 °C

Nämä putkiuunit voidaan käyttää vaaka- (RSH) tai pystyasennossa (RSV). Jaettu rakenne helpottaa työputken vaihtamista. Se mahdollistaa erilaisten työputkien (esim. eri materiaaleista valmistettujen työputkien) mukavan vaihdon.

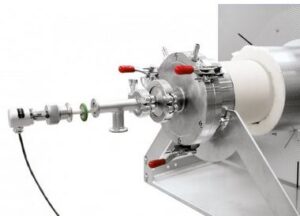

Laajan lisävarustevalikoiman avulla nämä ammattimaiset putkiuunit voidaan räätälöidä optimaalisesti prosessiisi. Lisäämällä erilaisia kaasunsyöttöpaketteja, voit työskennellä suojakaasuympäristössä, kaasujen kanssa tai tyhjiössä. Kätevien vakio-ohjaimien lisäksi prosessin ohjaukseen voidaan käyttää myös moderneja PLC-ohjaimia.

Ominaisuudet

- Tmax 1100 °C tai 1300 °C

- Yksialueinen suunnittelu

- Kaksoiskuorirakenne tekstuuripintaisista ruostumattoman teräksen levyistä lisätuuletuksella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan RSV-mallit pystykäyttöön tarkoitetulla kehyksellä

- Jaettu rakenne helpottaa työputken asettamista (avauslämpötila < 180 °C)

- Keraaminen työputki C 530, johon sisältyy kaksi kuitutulppaa käytettäväksi ilman kanssa

- Lämpöpari tyyppi N (1100 °C) tai tyyppi S (1300 °C)

- Kiinteät tilareleet takaavat hiljaisen toiminnan

- Tukiputkille asennetut lämmityselementit mahdollistavat vapaan säteilyn

- RSH: kytkentälaitteisto ja ohjausyksikkö integroitu uunin kuoriin

- RSV: kytkentälaitteisto ja ohjausyksikkö erillään uunista omassa seinä- tai lattiakaapissa

- Määritelty käyttö käyttöohjeiden rajoissa

- NTLog Basic Nabertherm-ohjaimelle: prosessitietojen tallennus USB-muistitikulle

- Ohjain B510

Pyörivät putkiuunit kokeelliseen toimintaan Tmax 1100 °C

RSRB-sarjan pyörivät putkiuunit soveltuvat eräkäyttöön. Työputken pyöriminen varmistaa, että kuorma liikkuu. Kvartsireaktorin muodon ja kapenevien putkenpäiden ansiosta erä pysyy pyörivässä putkiuunissa ja sitä voidaan lämpökäsitellä mielivaltaisen pitkän ajanjakson ajan. Myös ohjattu lämmitys lämpötilaprofiileihin on mahdollista.

Ominaisuudet

- Tmax 1100 °C

- Yksialueinen suunnittelu

- Kaksoiskuorirakenne tekstuuripintaisista ruostumattoman teräksen levyistä lisätuuletuksella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan

- Lämpöpari tyyppi N

- Kiinteät tilareleet takaavat hiljaisen toiminnan

- Tukiputkille asennetut lämmityselementit mahdollistavat vapaan säteilyn

- Putkiuuni on suunniteltu pöytämalliksi kvartsilasireaktorilla, joka avautuu molemmista päistä ja jonka päät ovat kapenevat

- Reaktori poistetaan tyhjentämistä varten pyörivästä putkiuunista

- Vyötön veto ja saranoitu uunin kuori (avauslämpötila < 180 °C) mahdollistavat erittäin helpon poiston.

- Säädettävä asema noin 1-40 kierrosta minuutissa

- Määritelty käyttö käyttöohjeiden rajoissa

- NTLog Basic Nabertherm-ohjaimelle: prosessitietojen tallennus USB-muistitikulle

- Ohjain B510 (5 ohjelmaa, joissa jokaisessa 4 segmenttiä)

Jatkuvaliikkeiset putkiuunit kokeelliseen toimintaan Tmax 1300 °C

RSRC-sarjan pyörivät putkiuunit soveltuvat erityisesti prosesseihin, joissa jatkuva eräaines lämmitetään lyhytaikaisesti. Nämä pyörivät uunit voidaan käyttää erittäin joustavasti eri tarkoituksiin. Pyörivä putkiuuni on hieman kallistettu ja saavutetaan kohdelämpötila. Materiaali syötetään jatkuvasti putken yläpäästä. Se kulkee lämmitetyn alueen läpi putkessa ja putoaa putken alapäästä ulos. Lämpökäsittelyn kesto riippuu kallistuskulmasta, pyörimisnopeudesta ja työputken pituudesta sekä eräaineen virtausominaisuuksista. Valinnaisesti saatavilla olevan suljetun syöttöjärjestelmän avulla pyörivää putkiuunia voidaan käyttää myös määritellyssä ilmakehässä tai tyhjiössä. Prosessista, erästä ja vaaditusta maksimilämpötilasta riippuen käytetään eri materiaaleista valmistettuja työputkia.

Ominaisuudet

- Tmax 1100 °C

- Työputki kvartsilasista, avoin molemmista päistä

- Lämpöpari tyyppi N Tmax 1300 °C

- Avoin keraaminen putki C 530

- Lämpöpari tyyppi S

- Kiinteät tilareleet takaavat hiljaisen toiminnan

- Tukiputkille asennetut lämmityselementit mahdollistavat vapaan säteilyn

- Kaksoiskuorirakenne tekstuuripintaisista ruostumattoman teräksen levyistä lisätuuletuksella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan

- Säädettävä asema noin 0,5-20 kierrosta minuutissa

- Digitaalinäyttöyksikkö pyörivän putkiuunin kallistuskulman näyttämiseen

- Jaettu uunin kuori (avauslämpötila < 180 °C) helpottaa putken vaihtoa

- Kompakti järjestelmä, pyörivä putkiuuni asetettuna peruskehikkoon

- Käsikäyttöinen spindeliasema kampikahvalla kallistuskulman säätöön

- Kytkentälaitteisto ja ohjaimet integroituna

- Pyörät

- Määritelty käyttö käyttöohjeiden rajoissa

- NTLog Basic Nabertherm-ohjaimelle: prosessitietojen tallennus USB-muistitikulle

- Ohjain B400 (5 ohjelmaa, joissa jokaisessa 4 segmenttiä)

Putkiuunit jalustalla horisontaaliseen tai vertikaaliseen työskentelyyn Tmax 1500 °C

Nämä kompaktit putkiuunit ovat käytössä, kun laboratoriokokeet on suoritettava vaaka-, pysty- tai tietyissä kulmissa. Kyky määrittää kallistuskulma ja työkorkeus sekä niiden kompakti muotoilu tekevät näistä putkiuuneista myös sopivia integroitaviksi olemassa oleviin prosessijärjestelmiin.

Ominaisuuet

- Tmax 1100 °C, 1300 °C tai 1500 °C

- Kompakti muotoilu

- Kaksoiskuorirakenne tekstuuripintaisista ruostumattoman teräksen levyistä lisätuuletuksella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan

- Pysty- tai vaakakäyttö säädettävissä rajattomasti

- Kulma säädettävissä rajattomasti 0:sta 90 asteeseen

- Työkorkeus säädettävissä rajattomasti

- Käyttö mahdollista myös ilman telineitä, jos turvaohjeita noudatetaan

- Keraaminen työputki C 530, johon sisältyy kaksi kuitutulppaa käytettäväksi ilman kanssa

- S-tyypin lämpöpari

- Kiinteät tilareleet takaavat hiljaisen toiminnan

- Lämmityslangat kierretty suoraan työputken ympärille, mikä johtaa erittäin nopeisiin lämpenemisnopeuksiin

- Ohjausjärjestelmä integroitu uunin jalustaan

- Määritelty käyttö käyttöohjeiden rajoissa

- NTLog Basic Nabertherm-ohjaimelle: prosessitietojen tallennus USB-muistitikulle

- Ohjain B510 (5 ohjelmaa, joissa jokaisessa 4 segmenttiä)

Korkean lämpötilan putkiuunit SiC lämmityselementeillä Tmax 1500 °C

Nämä kompaktit putkiuunit SiC-tangolla lämmityksellä ja integroidulla kytkentälaitteistolla ja ohjausyksiköllä soveltuvat monipuolisesti moniin prosesseihin. Ne edustavat edullista vaihtoehtoa korkean lämpötilan alueella. Vakioasennusvaihtoehdot lisävarusteille tekevät niistä joustavia erilaisissa sovelluksissa. Työputken rinnalle asetellut SiC-lämmityselementit takaavat erinomaisen lämpötilan tasaisuuden.

Key Features

- Tmax 1500 °C

- Kaksoiskuorirakenne tekstuuripintaisista ruostumattoman teräksen levyistä lisätuuletuksella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan

- Kuoren aktiivinen jäähdytys matalan pinta-lämpötilan takaamiseksi

- Keraaminen työputki C 799, johon sisältyy kaksi kuitutulppaa käytettäväksi ilman kanssa

- S-tyypin lämpöpari

- Kiinteät tilareleet takaavat hiljaisen toiminnan SiC-lämmityselementit, helppo vaihtaa

- Määritelty käyttö käyttöohjeiden rajoissa

- NTLog Basic Nabertherm-ohjaimelle: prosessitietojen tallennus USB-muistitikulle

- Ohjain B510 (5 ohjelmaa, joissa jokaisessa 4 segmenttiä)

Korkean lämpötilan putkiuunit horisontaaliseen tai vertikaaliseen työskentelyyn Tmax 1800 °C

Korkean lämpötilan putkiuunit ovat saatavilla joko vaaka- (tyyppi RHTH) tai pystymalleina (tyyppi RHTV). Korkealaatuiset eristysmateriaalit, jotka on valmistettu tyhjiömuovatuista kuitulevyistä, mahdollistavat energiatehokkaan toiminnan alhaisen lämmönvarastoinnin ja lämmönjohtavuuden ansiosta. Käyttämällä erilaisia kaasunsyöttöjärjestelmiä, toimenpiteitä voidaan suorittaa palamattomissa tai palavissa suojakaasuissa tai reaktiivisissa kaasuissa tai tyhjiössä.

Ominaisuudet

- Tmax 1600 °C, 1700 °C, or 1800 °C

- Single-zoned design

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Insulation with vacuum-formed ceramic fiber plates

- Tube furnaces RHTV with frame for vertical operation

- Type B thermocouple

- Solid state relays provide for lownoise operation

- Tmax 1600 °C, 1700 °C tai 1800 °C

- Yksialueinen suunnittelu

- Kaksoiskuorirakenne tekstuuripintaisista ruostumattoman teräksen levyistä lisätuuletuksella matalan pinta-lämpötilan saavuttamiseksi

- Eristysmateriaalien yksinomainen käyttö ilman luokitusta EC asetuksen nro 1272/2008 (CLP) mukaan

- Eristys tyhjiömuovatuilla keraamisilla kuitulevyillä

- Putkiuunit RHTV pystykäyttöä varten suunnitellulla kehyksellä B-tyypin lämpöpari

- Kiinteät tilareleet takaavat hiljaisen toiminnan